RESEARCH & DEVELOPMENT

GRECIAN MAGNESITE places special emphasis on research and development and has a dedicated R&D center operating since 1993. The R&D supports the company to meet the industry's technological challenges and contributes significantly to the success of the company’s development strategy and the design and marketing of specialty and high added value products. The R&D also promotes the optimal exploitation of natural resources by careful identification and study of all ore characteristics in relation to product and production technology developments.

The R&D center operates in a remote, modern, fully-equipped facility, staffed with high caliber personnel, in Vassilika, Thessaloniki, serving a fourfold pro-active purpose:

- Develop new products for new and existing applications

- Carry out applied research to continuously improve final products characteristics and application know-how

- Offer technical support to production (quality and new products)

- Offer specialized technical support and after sales service to the customers

The R&D participates actively in a variety of national, EU and own-funded research projects and cooperates with the local and international industry and academia. Some example research areas are the following:

- Monolithic refractory formulations based on Dead-Burned MgO and Dunite

- Eco Magnesia based cements

- Utilization of by-products and beneficiation of mining waste

- Reduction of the company’s environmental footprint: Carbon Capture and Utilisation, Flue gas emission control, Use of alternative Fuels and production techniques.

- Development of caustic calcined MgO for hydrometallurgical applications (e.g, production of nickel and cobalt)

- Development of high purity natural MgO for high-end applications such as magnesium compounds, catalysts and polymers

- Unique property and world-wide breakthrough MgO for tanning applications

- Unique low iron MgO grades for electrical applications

- Special Dead-Burned grades for welding fluxes

- Special magnesium carbonate grades for ceramic applications

Another important task of the R&D is the follow-up of European Regulations related to the company’s activities (e.g. EU-ETS, BREFs/IED, REACH).

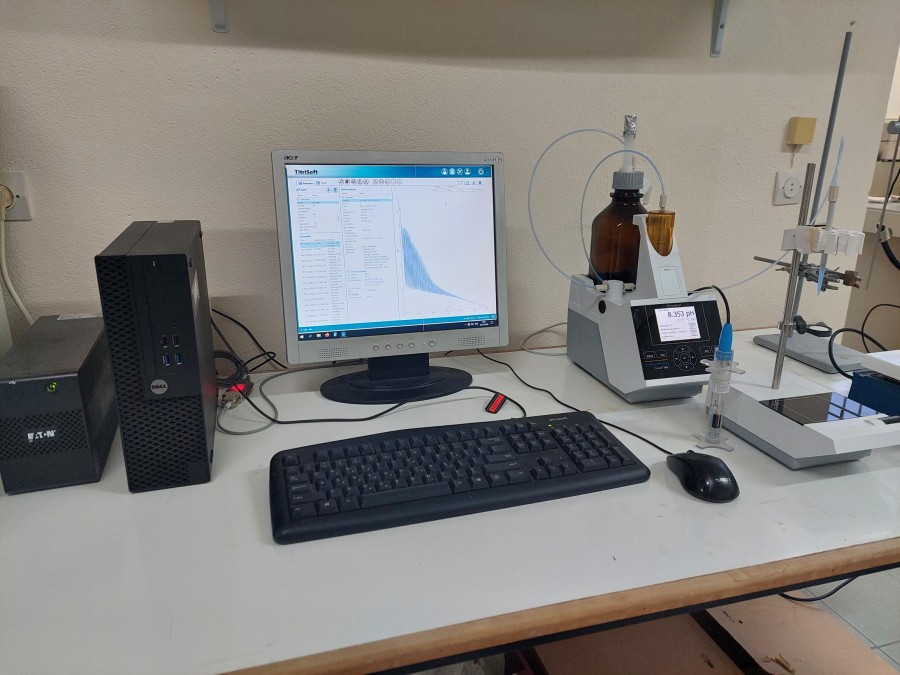

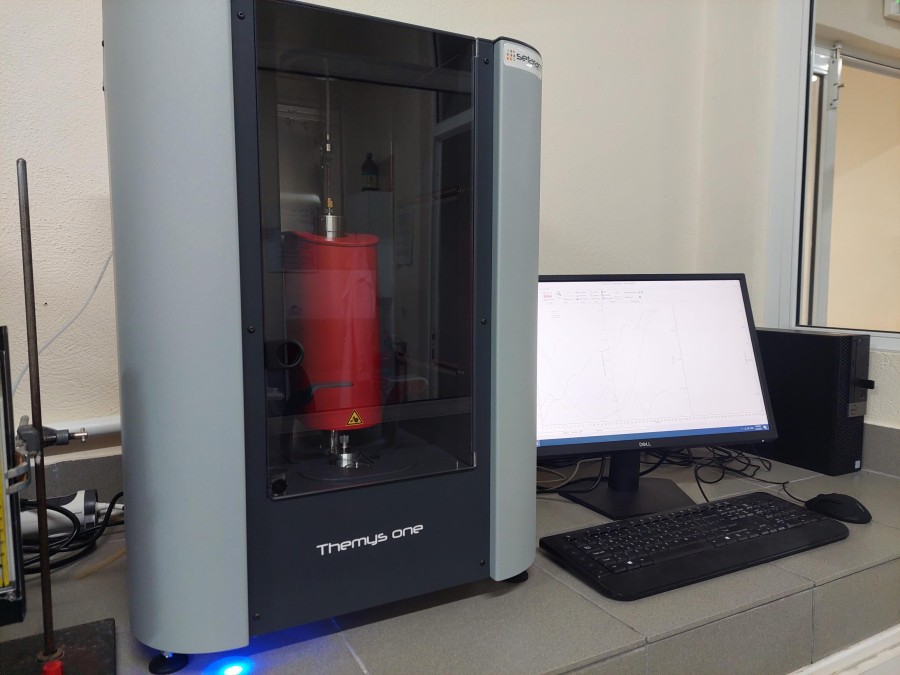

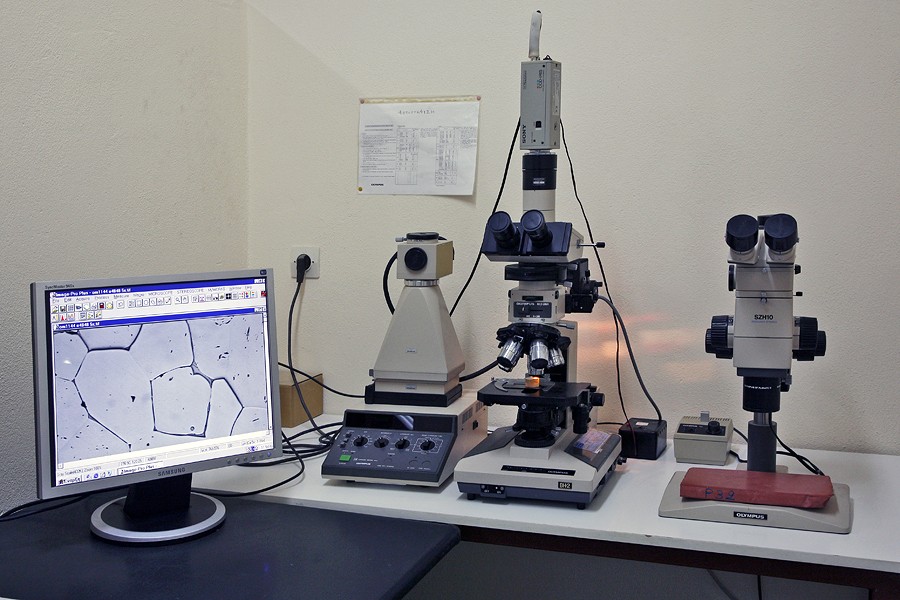

The R&D center’s infrastructure allows the study of applications and a thorough characterization and evaluation of materials. Implemented techniques include:

- X-Ray diffraction for the study of mineralogy and crystal properties

- Microscopy for the study of material microstructure

- TG-DTA/DSC for high accuracy thermogravimetric analysis of industrial mineral samples

- Nitrogen adsorption for Surface Area and Porosity analysis

- Atomic Absorption Spectroscopy

- Laser Diffraction of powders

- Automated measurement of Vicat Setting properties

- Determination of mechanical strength and abrasion resistance

- Heat treatment/Firing of materials in ovens and high temperature furnaces

- Determination of acid reactivity and acid insoluble content

- Automatic titrator able to perform endpoint, linear, dynamic and pH-Stat titrations. It is invaluable for the characterization of CCMs and DBMs, the determination of reactivity towards acids and the lab simulation of several applications